It has been nearly a year since the Recycled Material Standard launched with its first accredited certification body and initial group of certified participants. As the program gains recognition, we have had many conversations with companies throughout the plastic supply chain that see the value of certification and are looking to pursue RMS certification in the not-too-distant future.

GreenBlue is in a period of unprecedented growth for many of our programs, including Sustainable Packaging Coalition and How2Recycle. Companies throughout the value chain are increasingly engaged in the sustainability of their packaging, and we see that reflected in membership numbers. Both SPC and H2R have followed exponential growth curves. In their early days, there was a smaller group of initial supporters, but they are now seeing substantial growth, as more and more companies prioritize sustainable packaging. We expect to see RMS follow a similar pattern, as we think the moment is ripe for companies to embrace certification of recycled materials and take advantage of some of the new tools that certification can offer.

Earlier this month, the Ellen MacArthur Foundation released its most recent New Plastics Economy Global Commitment progress report. While progress is being made against the Global Commitment’s goals to increase the use of recycled content and cut virgin plastics use, it has become clear that companies are not on track to meet their 2025 goals.

The fact is, we need flexibility to advance the use of recycled materials. We improve sustainability not necessarily by putting recycled content physically in any one particular type of package, but by moving more recycled materials through the larger supply chain, displacing the use of virgin materials, and creating incentives for more materials to be collected.

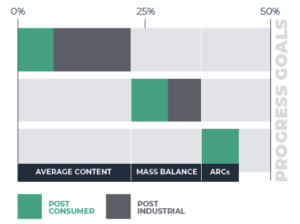

The RMS has tools that can help companies achieve these aims. Mass balance accounting gives companies operational flexibility to apply recycled material claims where they are needed most, and enables chemical recycling technologies to scale by taking advantage of existing infrastructure. Attributes of Recycled Content, or ARCs, are a new environmental commodity that allow users of plastic to directly support investments in new recycling infrastructure. While ultimately, we hope that the need for these tools diminishes as more and more of the plastic we use is recycled, in the near term, companies can combine these tools with more conventional use of recycled content to make progress toward their goals.

Supply chain participants are starting to acknowledge the need for this flexibility. Gerard Selvaggio, Partner at BlueClover said “At BlueClover we work with both resin producers and buyers – primarily in polypropylene. As companies scramble to buy recycled material as a physical commodity it will be hard to fill the pent-up demand with existing supply. But we see great potential and possibilities in the ARC trading system.”

Meanwhile, policymakers and business leaders are beginning to recognize the value of certification. State policies are starting to include language supporting certification for recycled materials. For example, in January of this year, New Jersey signed into law a recycled content mandate that includes language allowing state regulators to require third-party verification of recycled content claims. California’s SB54 provides a pathway for alternative compliance through the transition to use of certified post-consumer recycled materials. Chain of custody certification will be valuable for demonstrating compliance with minimum recycled content requirements and other legislation coming into effect in numerous states in the coming years.

Retailers are also starting to embrace and celebrate sustainable product certifications. You may have come across Amazon’s recently launched Climate Pledge Friendly designation, but they aren’t the only retailer with a new focus on certifications. Last month, Wayfair launched its Shop Sustainably program, featuring over 50 third-party sustainability certifications, including RMS. These types of programs will make it easier for consumers to find more sustainable products and be assured that claims are legitimate.

In conversations with companies throughout the value chain, we have seen increased recognition of the value of the flexibility and accountability RMS offers. We have been taking steps to make sure RMS is ready to support new participants who are interested in learning more and pursuing certification:

- We recently released updated one-pagers: Features & Benefits, Attributes of Recycled Content (ARCs), Mass Balance, and Post-Industrial Plastics, with information on the features and benefits of RMS, as well as how it addresses post-industrial materials and how mass balance accounting and ARCs work.

- We have been engaging with key stakeholders to get alignment around principles for supporting certification of recycled materials.

- We are currently in the process of a pilot with a second certification body. This will provide participants with more options, and foster some healthy competition among certification bodies.

We are prepared, and prospective participants see value in certification. While it will take time to get full supply chains certified, we have high hopes that 2023 will be a year of substantial growth for the RMS.